Projects

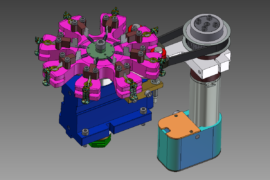

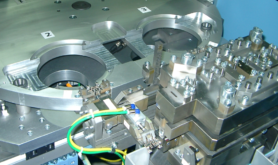

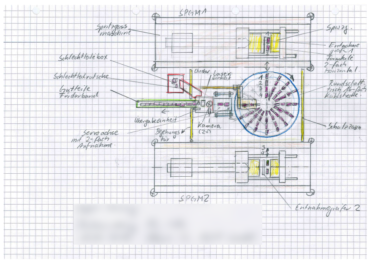

AEF high speed rotary indexing table (swivel time 0.16s) for complex measuring tasks of cycle times < 1 second and collet technology

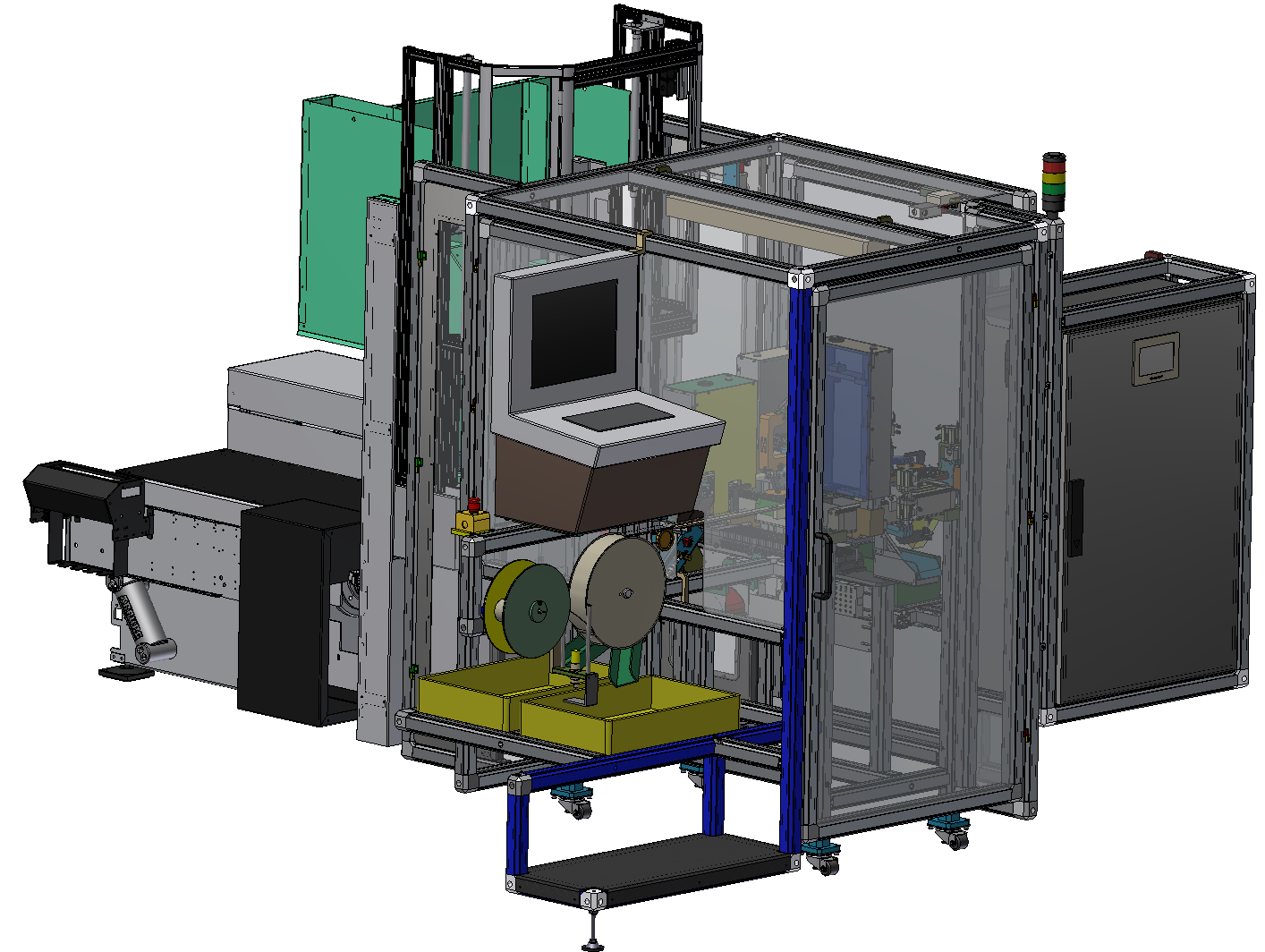

cycle time optimized, durable and low-maintenance systems in the smallest space

- design in 4 degrees of freedom

- multiple splitting of complex processes

- implementation of basic mechanics

- weight-optimized exercise units

- hardened, eroded precision guide systems

- specially developed durable basic components

- use of high-quality components, e.g. high-performance servo motors

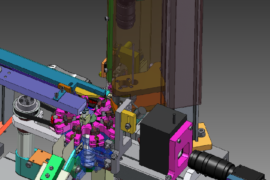

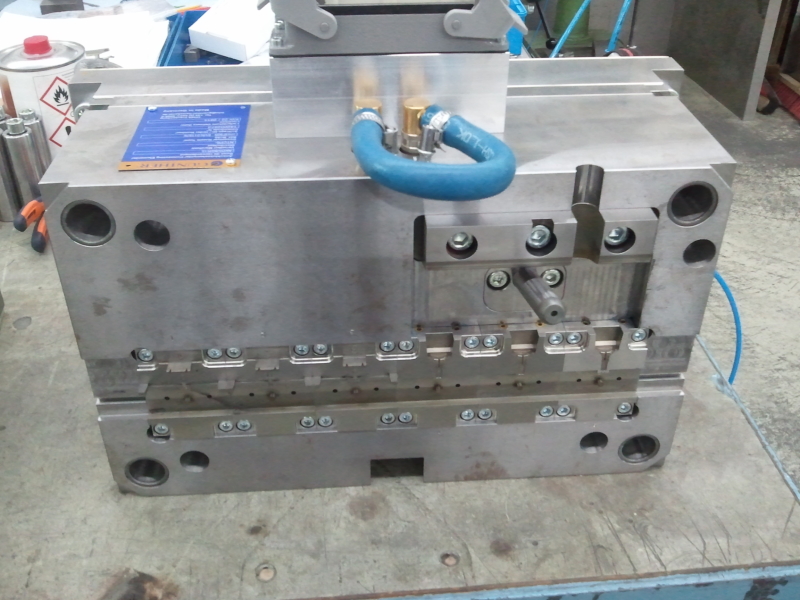

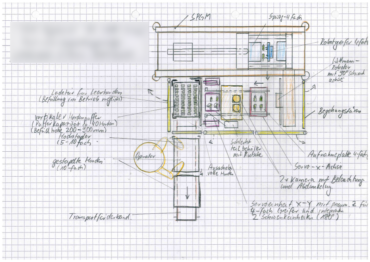

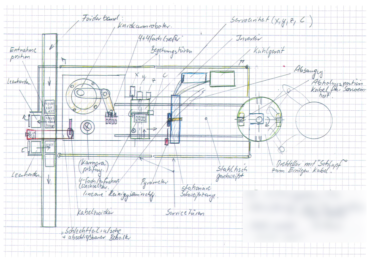

- automated injection mold

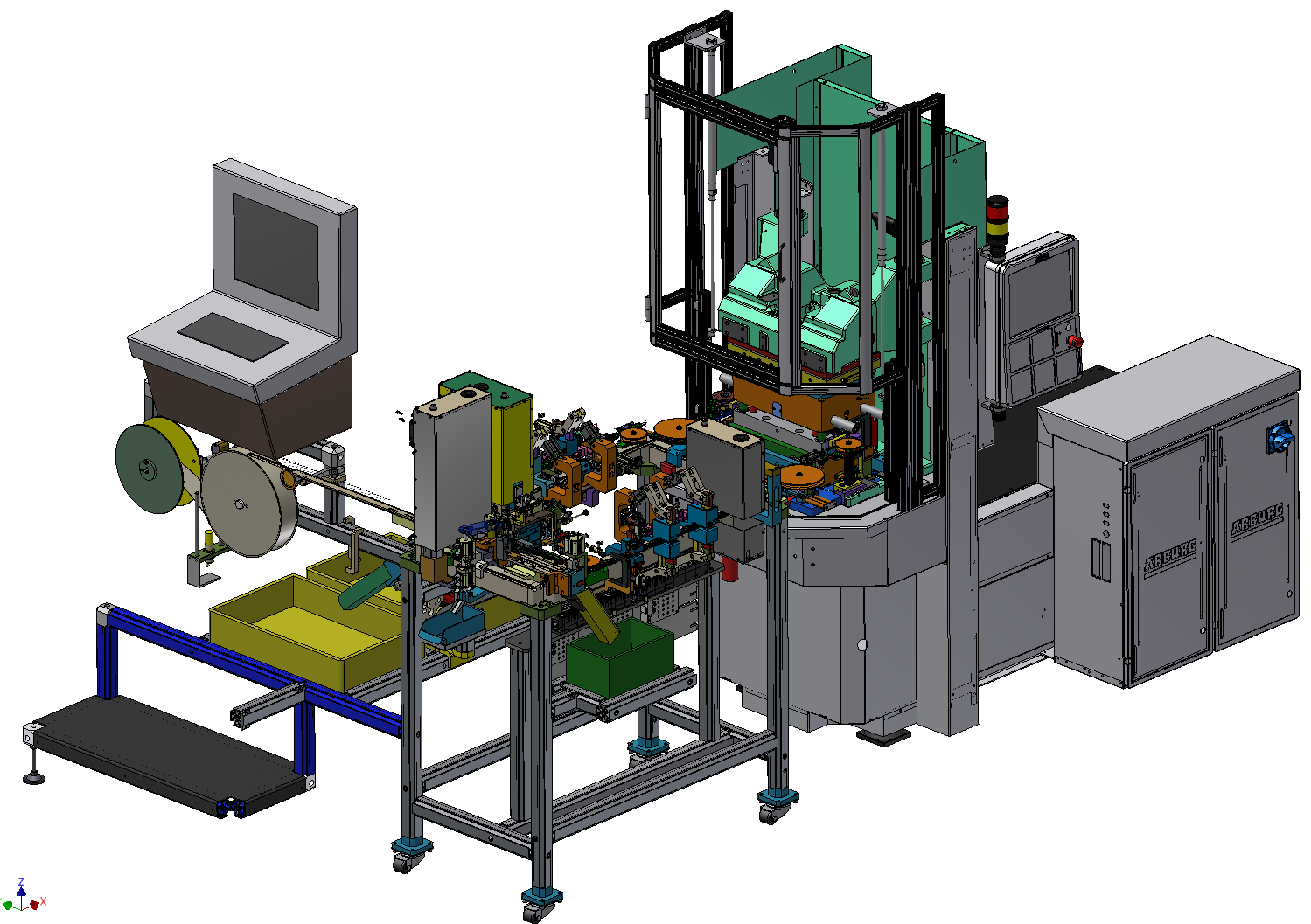

- implementation of the injection moulding machine

- loading and unloading equipment

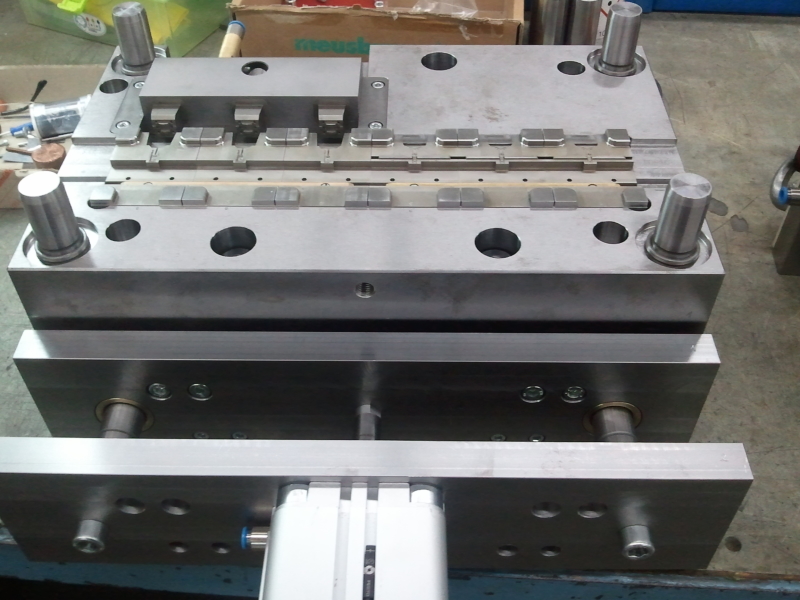

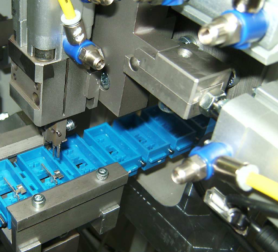

- automation-oriented injection moulding tool

- integration-capable automation and test engineering

- wire feeding technology

- contacts from punched strips with a punch

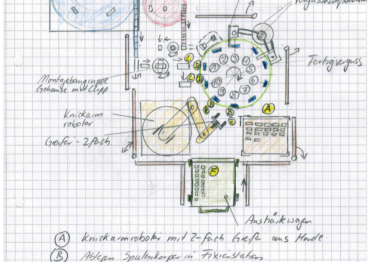

Complete solution of an automated injection moulding machine

Injection mould with rotating chain system by injection moulding machine with punching, bending, injection moulding and measuring requirements

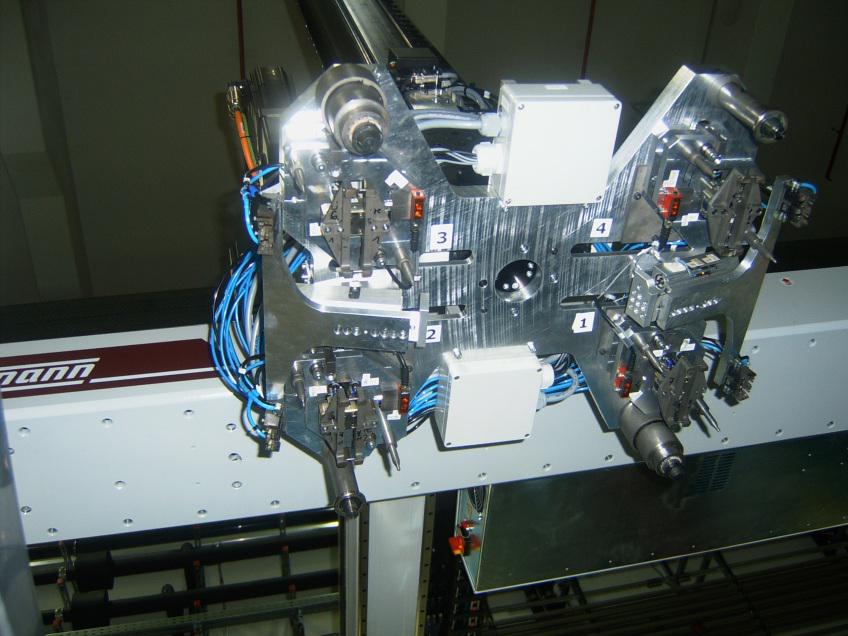

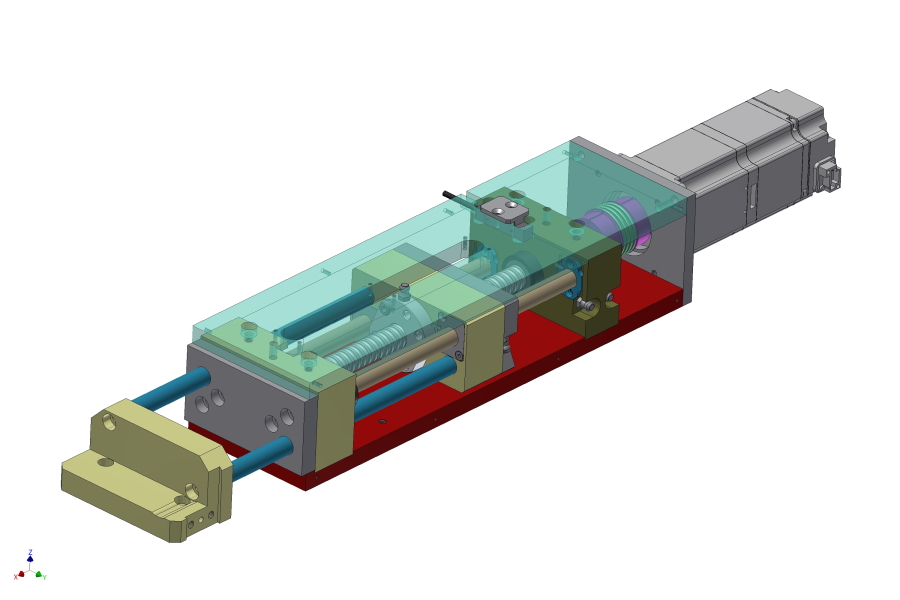

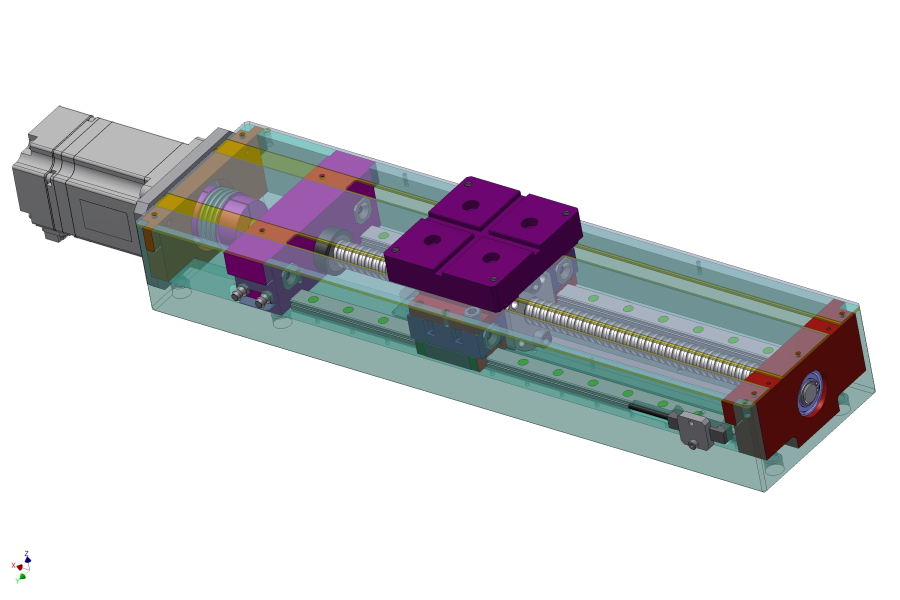

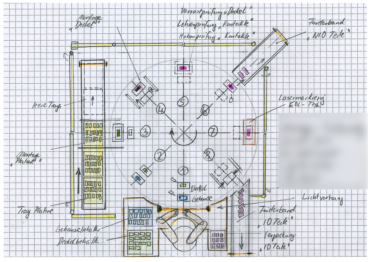

The suitable workpiece carrier system for the respective suitable requirement

- linear Systems

- AEF servo axes

- circulating metal workpiece carrier

- circulating plastic workpiece carrier

- magazine from injection moulded workpiece carrier

- chain from injection moulded workpiece carrier

- chain of hardened precision workpiece carrier

- round plate systems

Insert technology with upstream and downstream automation and measuring technology